Fibre-reinforced concrete (FRC) is becoming increasingly popular across the construction industry due to its many advantages, including strength enhancement, crack resilience properties, and onsite time savings, especially when compared with traditional rebar setting.

Whether using steel fibres, synthetic polymers, or nylon strand fibre, these reinforcements offer enhanced structural performance, crack control, and impact resistance. They fall into the micro (enhanced crack and spalling prevention) and macro (structural performance) types.

Despite FRC reaching a stage of proven development and increasing industry confidence, pumping fibre-reinforced concrete still presents a unique set of challenges, which are often less understood.

These challenges arise from the key differences in FRC to conventional mixes: flow and slump behaviour, abrasiveness, and particle size and shape. For readymix plants aiming to produce and deliver FRC without frustration, high costs, and delays, overcoming these challenges is key to quality, efficiency, and profitability.

Fibre Types and Their Impact on Pumping

Steel, Synthetic, and Nylon Fibres: What Changes?

Concrete fibre additives vary in material, length, shape, and rigidity. Each of these variables affects how well the concrete can be mixed, pumped, and placed.

Certain fibre materials can affect the flowability more than others, making it more difficult to pump. This is due to the fibres affecting the water’s ability to “lubricate” the concrete mix. RFC can appear ‘drier’ than its non-reinforced state, so avoid the temptation to over-water. It is generally better to add plasticisers rather than additional water to the mix, although check this out with your material supplier.

- Steel Fibres: Often designed with hooked ends, crimped profiles, or rough-cut edges to maximise anchorage in cured concrete. However, these very features can:

- Create turbulence and interlocking during flow

- Increase abrasion inside pumps and pipelines

- Accelerate wear, especially at high rotational speeds and flow rates

- Cause clumping or balling, particularly in standard concrete pumps and incorrectly sized pipes

- Synthetic/Nylon Fibres: While less abrasive, these still raise viscosity (resistance to flow), and dispersion issues can arise. Long synthetic fibres in concrete tend to align with the linear flow direction, which weakens reinforcement properties by reducing multidirectional anchorage and stress distribution in the final product.

A notable issue with these fibres is their lighter density, which isn’t a problem in fresh batches but can cause issues in the wastewater. Concrete washout water and site runoff are usually collected in wedge pits, where the heavy silt naturally settles and the clearer water is drawn off the top. However, the lighter density of polypropylene fibres makes them more likely to float near the surface, where they are taken into pumps that aren’t usually designed to handle solids. Entanglement and blockage then occur, requiring a time-consuming and potentially high-risk manual intervention to clear the problem.

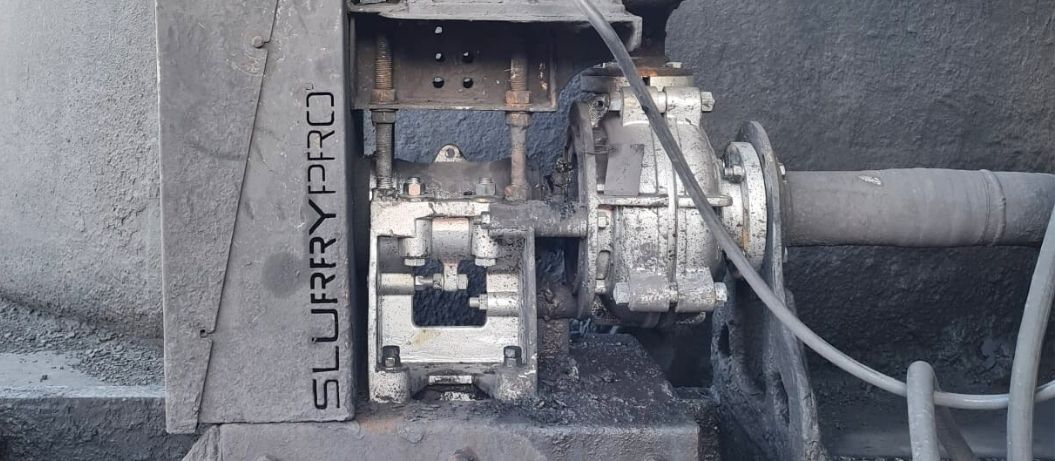

RMX sites producing FRC on a regular basis have found upgrading their wedge pits pumps to the Audex range reduces the frequency of blockages and replacements, as their material and design are optimised for passage of high-wear solids.

An alternative to a concrete wedge-pit pump upgrade (or as an additional protection) is the fibre filter from Atlantic Pumps. This is basically a cage that fits around the submersible pump (or suction pipe) that has sloping sides like an upside-down pyramid. This keeps most fibres out of reach of the pump and allows deposits to fall away and settlle, between pumping duties.

Mix design – adhere strictly to your fibre supplier’s specification and technical information. The manufacturer will have determined the best fibre material, geometry and dose rate for the required performance, and should have tested this to the relevant standards to meet regulations.

Your pump system’s capability might determine the range of FRC mixes you can offer, so ask your supplier what options and upgrades are available.

Pump compatibility – higher pressure may be needed, without increasing (and preferably decreasing) the flow rate.

Fast flow and high rotation speeds increase the wearing effect of abrasive fibres. Standard concrete pumps tend to cause clumping of the fibres, where they ball up and lead to blockages in the pipe.

Gearing the pump down is a common way to increase pressure and decrease flow, although check the safe limits with the pump supplier. High wear-resistance pumps are essential.

Dispersion, flow resistance, and strand orientation.

Dispersion: the Make-or-Break issue for FRC

Consistent and even dispersion of fibres throughout the concrete mix is paramount for successful outcomes. Clumps of fibres can cause blockages, uneven flow, and damage to the pump. Aside from the practicality of pumping, even dispersion is essential to achieving the specified properties of the final cured concrete. This requires pumps that do not promote segregation and omnidirectional re-orientation of the fibres.

Slow-speed mixers and in-line dispersion are good for ensuring proper wetting and separation of the fibres.

Post-mixing transport and pump placement

Having achieved your perfect mix, you don’t want to lose the properties through inadequate transportation.

Lower flow rates and minimising pumping distances can help avoid disturbances to the distribution and orientation of the reinforcement. Some concrete suppliers prefer to pump a base mix to the pouring location, then inject the fibres in the concrete at this later stage, using a dosing pump. However, this is unnecessary with the correct delivery system.

Long concrete strengthening fibres are more prone to orienting themselves in the direction of flow, adversely affecting the final cured properties of the concrete. Short fibres are prone to balling as they tend to rotate around the pipe wall. A good guide is to match fibre length to 50% – 60% of the hose diameter.

Washout Water and Wedge Pit Emptying

Concrete washout water and fibre recovery: Many pumps that are suitable for handling truck washout water and yard run-off are made to cope with silt and high pH conditions, but can struggle with strengthening fibres. The fibres are prone to block the system, and steel types in particular can cause premature wear of pumps. Filter-traps, like those made by Atlantic Pumps, are a straightforward way to combat this. They fit around sump pumps, reducing the number of fibres that reach the intake. For those that do slip through, heavy-duty pumps such as the Audex AS range can easily cope, as they are built for high-wear, high-pH applications, and suspended solids.

On large RMX plants which collect a lot of fibres in their wastewater, it can be feasible to separate out and recycle them for cost and sustainability benefits. The optimum separation technique depends on the size and material of the fibre strips, but the options are typically filtering, settlement, or centrifugal separation. Sometimes, silt and fibres can be separated in the same process; heavy silt is drawn out through the underflow, and low-density fibres flow over a top weir.

This processing reaps environmental and cost benefits through water and fibre recovery for reuse.

At Atlantic Pumps, we are here to help you make the right choice in every decision. We have in-depth knowledge about pumping challenging fluids, which is why we have put together a free downloadable guide that will help you discover the wide range of pumps available for your industry. If you would like more information, please get in touch, and we will be happy to help you.

We also take a sustainable approach to our work and are committed to reducing energy waste from pumps. Our expert knowledge allows us to reduce energy usage by 20% on the average site!

Call us today on 0808 196 5108 for more information.

July 14 2025

July 14 2025 4 min read

4 min read