Effective wastewater treatment is critical for ensuring environmental sustainability and public health. Yet, one persistent challenge in this field is managing grit and its long-term impact on sludge pumps. This abrasive material can wreak havoc on equipment, leading to increased maintenance costs, reduced efficiency, and unplanned downtime. To mitigate these effects, wastewater professionals must understand grit’s characteristics, its sources, and effective management strategies.

What is grit in water treatment?

The term ‘grit’ in water treatment refers to dense, inorganic particles that make their way into wastewater systems. These particles, known for their hardness and abrasiveness, create significant operational challenges for pumps, particularly sludge pumps. Composed predominantly of silica-based materials and small aggregates, grit causes accelerated wear and tear on many internal pump components, adding substantial strain to wastewater treatment operations.

Common types of grit

- Sand and gravel from erosion and construction runoff.

- Cinders from industrial processes or urban environments.

- Eggshells from domestic kitchens and food processing factories.

- Inorganic particulates with varied sizes and densities.

Common to earthworks and groundwater is sand – primarily made up of silica, a material known for its toughness, and this grit’s high abrasiveness is often the root cause of premature wear on internal pump components. While its composition can vary slightly based on source, its destructive potential remains consistent. If this is the duty, ensure that you choose pumps that are built with hear-wear resistant materials.

Where does grit come from?

Grit typically originates as debris carried by water flows, heavily influenced by its environment and source. Without proper removal and management, this material damages key equipment, resulting in inefficient plant operations and heightened repair costs.

Typical offenders include:

Understanding grit’s properties and origins is therefore essential for addressing its impact on your sludge pumps. Below are key characteristics and sources of grit within wastewater systems:

- Surface runoff: Rainwater washing over roads, pavements, and construction sites carries grit-laden debris into the sewer systems.

- Infiltration: Groundwater seeping into sewer pipes often deposits grit, particularly in areas with ageing infrastructure.

- Household waste: Material introduced via kitchen disposals or poorly filtered household drains contributes substantial quantities of grit.

- Industrial discharges: Certain sectors, such as construction or food processing, send wastewater containing significant grit levels into shared treatment networks.

How does grit impact sludge pumps?

Sludge pumps are specifically designed to handle viscous, high-solids-content wastewater, but grit poses significant challenges even for the most robust systems. In the UK, most wastewater companies design their removal systems to target particles of 200 microns or larger; however, studies have shown that up to 35% of grit found in anaerobic digesters is actually smaller than this threshold, allowing considerable abrasive material to bypass removal processes and cause damage downstream. The abrasive particles impair a pump’s efficiency over time and can accelerate wear, leading to a range of operational challenges:

- Component erosion: Grit particles erode impellers, casings, and seals within sludge pumps. Cumulative exposure increases clearances between components, reducing overall pump efficiency and degrading its ability to deliver the required flow and pressure. This is why pumps able to withstand high levels of wear and tear due to grit particles are excellent options that can help businesses save significant amounts of money. For example, Arthur’s Waste Management business followed our recommendation to replace their progressive cavity pump with an LSM pump and is saving £20K a year as a direct result.

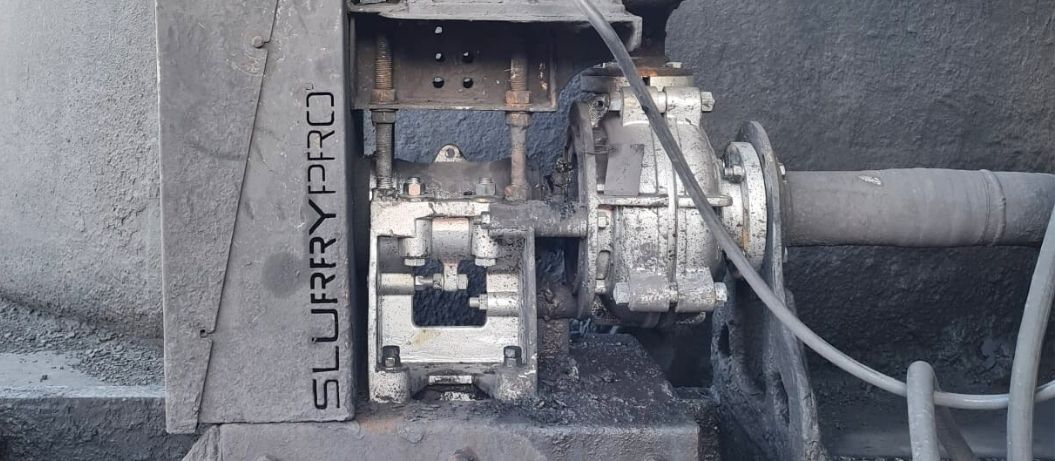

- High operating costs: Frequent contact with grit necessitates regular equipment repairs and part replacements. The maintenance burden grows as components degrade. Notably, capital costs represent only 5–10% of a pump’s total 20-year lifecycle expense, with the bulk of total expenditure attributed to ongoing maintenance and energy use. However, when improperly maintained, pumps can fail quickly and easily, which could also lead to extra costs due to downtime. In this instance, we would recommend pumps with reduced maintenance needs, such as SlurryPro. One of our customers, Viridor, was looking for a way to reduce downtime and wear life of its pumps to ensure the company met their annual goals. After switching to SlurryPro, following our recommendation, this company is now able to predict a steady energy consumption and has reduced its maintenance costs, as the length of time between maintenance for the pumps has been improved by 3 to 4 times.

- Energy inefficiency: As abrasive wear takes its toll, pumps must work harder to maintain flow rates, resulting in higher energy consumption. This not only inflates energy costs but also makes it harder to meet regulatory targets for energy efficiency.

- Downtime and reliability Issues: Grit-induced failures can halt wastewater treatment processes unexpectedly. Downtime impacts organisational performance, affects compliance with service-level agreements, and can jeopardise regulatory standing. However, implementing advanced technologies can yield significant savings. For example, Severn Trent Water adopted reactive pump control technology across several sites—an innovation that reduced pumping time and maintenance, leading to annual savings of £100,000.

To safeguard your sludge pumps from the challenges associated with grit, wastewater facilities employ a combination of preventive and corrective strategies. Below are some of the key measures:

Grit Chambers: These settling tanks slow the flow of wastewater, allowing grit particles to sink to the bottom for removal.

Hydrocyclones: Centrifugal devices that separate grit from water through rotational motion, ensuring enhanced removal efficiencies.

Vortex Separators: Equipment that creates a controlled swirl in the flow to force grit particles outward for easy extraction.

Regular Maintenance Protocols: Routine maintenance is essential to avoid long-term damage. Best practices include inspecting pump impellers, casings, and seals for visible signs of wear, replacing components promptly to maintain peak operational efficiency, and monitoring pump condition using pressure gauges and shutoff valves to compare operational pressures against original rated conditions.

Innovative pump designs: Modern sludge pumps are integrating advanced design features to withstand grit better. Wear-resistant materials such as high-chrome steel and other hardened alloys can also help improve pump longevity. Depending on the average particle size of the grit (the d50), rubber linings can be the most cost-effective method of protecting pumps and pipes from excessive abrasion.

Grit in water treatment: Find out more

While grit is an unavoidable reality in modern wastewater systems, its long-term damage to your sludge pumps and maintenance budget doesn’t have to be. Facilities across the UK can mitigate grit’s impact by adopting state-of-the-art removal processes, prioritising routine maintenance, and investing in robust pump technologies designed to endure tough operating conditions. To find out more, please download our free guide: Managing Sludge and Grit.

We also take a sustainable approach to our work and are committed to reducing energy waste from pumps. Our expert knowledge allows us to reduce energy usage by 20% on the average site!

Call us today on 0808 196 5108 for more information.

September 17 2025

September 17 2025 5 min read

5 min read