Submersible pumps are a type of industrial pump that has been designed to be submerged in water (or other liquids and fluids). They tend to be considered more efficient and convenient than traditional pumps, thanks to their ability to ‘push’ water instead of ‘pulling’ it. Usually connected to a hose or a pipe, submersible pumps tend to be characterised as versatile and efficient solutions for many type of pumping issue, from residential to industrial, and from holding tanks to sump dewatering.

Submersible pumps are a critical component of many site dewatering systems and industrial processes. They are equipped with an electric motor which is hermetically sealed and lubricated via an internal oil bath. This allows them to be fully submerged in the sump, reservoir, or storage vessel, doing away with the need for a suction pipe and making them self-priming.

Whilst these types of pumps offer multiple benefits, we have selected a handful of features we think are most remarkable and useful to your day-to-day operations. Some of the advantages of submersible pumps include:

Self-Priming

Since the fluid automatically floods the inlet, they never need priming, overcoming the lack of suction lift that other centrifugal-type pumps can suffer from. This helps streamline operations, particularly where the duty involves intermittent or ad-hoc running. However, it is important to keep in mind that it is essential for the pumps to be properly submerged when running, for maximum performance and pump longevity.

Reduced Risks of Overheating and Cavitation

Electric submersible pumps work on a similar principle to traditional dry-sited centrifugals, apart from the fact that they are built to work underwater. Once the motor has been activated, the impeller begins to rotate rapidly, using centrifugal force to create upward flow.

With any pump being susceptible to overheating (from current draw and friction), this common concern is mitigated; the equipment is entirely submerged in liquid, which helps absorb excess heat that would otherwise damage the motor or internal parts.

This immersion, when coupled with an auto-off switch, also reduces the pumps’ risk of cavitation, therefore enhancing their reliability and longevity.

Correctly choosing your pump, to match your application, is a crucial factor to ensure the longevity and efficiency of your pump. For more information on the subject, please read our article, which highlights what you need to consider before purchasing a submersible pump. The motor and pump is protected from overheating by the surrounding water body.

Automation:

One essential feature of electric submersible pumps is the ease of automation by utilising a simple float switch. This feature acts as a protective measure, automatically activating the pump when water levels rise and switching it off when the supply is low. Float switches are a great way to prevent overflow and dry-running, ensuring the pump works when needed without any manual intervention. Different submersible pumps will come with different features as standard, but automated on/off controls, such as simple mechanical float switches, can easily be added.

All In One:

As the pump and motor are all encased in one robust housing, it is easier to move them without disturbing the motor and shaft alignment. This makes them more portable than their dry-sited equivalents, ideal for mobile working and project-based contractors.

Quiet & Clean Operations:

Although all electric pumps are inherently quieter than diesel-powered ones, submersible pumps have additional sound-proofing from the water or liquid in which they are contained, making them ideal for areas where noise reduction is essential, such as residential neighbourhoods.

The advantages of submersible pumps can truly help increase the efficiency in industrial sites, and are frequently used in support of corporate sustainability programs, especially when renewable electricity is available. They are key components of safe site operations, and if properly selected for the right application, are extremely reliable and durable, helping to meet operational deadlines and quality standards.

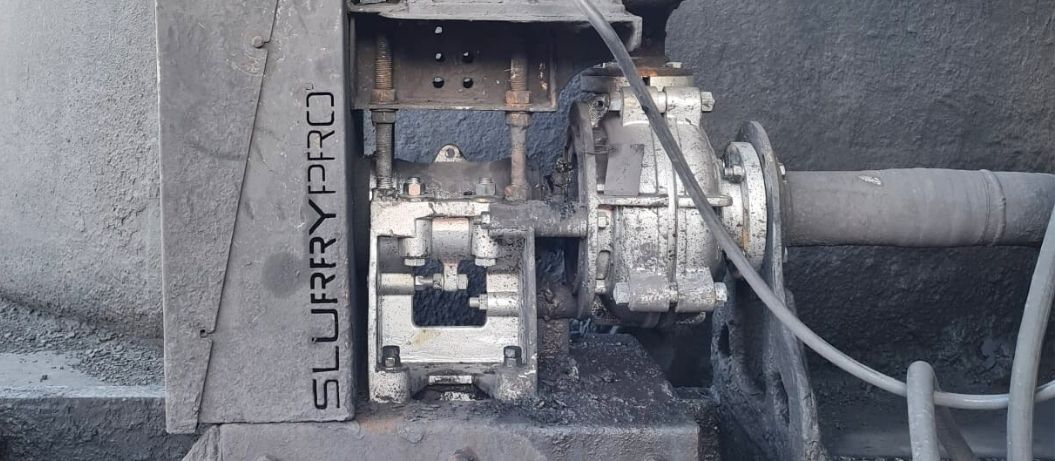

At Atlantic Pumps, we offer a wide range of submersible pumps, suitable for all types of needs, including high-wear dirty water and slurries such as silt runoff. If you would like any additional information about our pump solutions, please get in touch, and a member of our team will help you. If you would like to learn more about submersible pumps, we have put together a guide to reduce submersible pump downtime.

We also take a sustainable approach to our work and are committed to reducing energy waste from pumps. Our expert knowledge allows us to reduce energy usage by 20% on the average site!

Call us today on 0808 196 5108 for more information.

June 11 2025

June 11 2025 4 min read

4 min read