The Energy from Waste (EfW) sector is rapidly evolving to meet the growing global demand for sustainable waste management and renewable energy. Central to these operations are pumping systems, which must cope with a wide variety of feedstocks and operational conditions.

Unlike dedicated energy crop feedstocks, pumpage in municipal household waste processing, and even in segregated food waste-streams, often involves large solids, textiles, metal sharps, unspecified chemicals, abrasive grits, broken glass, bone fragments, etc.

For farm and agricultural-based EfW, plus certain food waste, the feedstock is generally predictable and homogeneous, with a much more consistent particle size. This makes pump selection and specification easier, although fibrous build-up and tangling can still create blockages.

Soil left on root crops can be easily washed off the surface before being crushed or shredded, meaning little to no grit enters the system. Fruit stones are of a known size and density, allowing for a relatively straightforward selection of pump and impeller passage size.

Such luxuries are not available to the EfW operator, who must deal with whatever is tipped.

This variability introduces unique complexity into waste handling and pumping, from the mechanical pre-treatment stage, through feedstock homogenisation stages, to final digestate dewatering and washdown water treatment.

What solids-size clearance do you allow for? What is the likely pH range? Will that abrasion-resistant grit forwarding pump cope with the impact of larger solids like sharp cutlery and flint?

How do you factor wear-induced slippage into calculating flow and pressure (head) requirements?

All this means that turnkey packages designed for agricultural feedstocks don’t take well to processing municipal and industrial wastewater streams.

The early days of anaerobic digestion (AD) treatment of waste began in dairy farms, this technology was then ‘stretched’ into other more challenging waste streams. Thankfully, as the market has matured, new pumping technology has been developed to specifically address the additional challenges.

Explains Andy Smith, MD of Atlantic Pumps “We’ve helped optimise many EfW and AD sites that were originally kitted out with equipment more suited to less challenging duties, such as clear water pumping, energy crop digestate and homogenised farm slurry. The results are truly rewarding for us and the client, with clear cost savings and resource recovery rate increases”

Incineration is a common way of turning mixed municipal non-recyclables. This invariably involves extreme heat, abrasive slurries, and corrosive pH liquids at the various stages: recirculation of cooling water and heat exchange fluid, treating fly ash and bottom ash sludge, sump water pumping etc.

Advanced Anaerobic Digestion (AD) is used in both Agri-energy and EfW facilities. These do share many similarities, but mixed feedstocks require additional pre-treatment steps.

In industrial and household waste, and even ‘food’ waste, grit usually builds up throughout the system, despite best efforts to remove it at the headworks intake. Fats, oils and greases (FOGs), mixed sized non-biological/non-flammable solids are entrained, and resilient textile fibres combine to cause a myriad of issues.

Solids-handling

There is a big difference between soft solids and hard solids when it comes to abrasion and impact damage.

Chopper pumps can work well for cutting rag and soft solids, allowing them to pass through pump impellers. However, the chopper components can quickly get destroyed when hard solids come through. Due to the speed of rotation necessary for effective rag-fibre cutting, even small grains of sand can cause accelerated wear of the cutter blades.

Early-stage removal of mineral solids is key, as chopper pumps themselves can make downstream separation and dewatering more complex by increasing the amount of fines, such as glass dust.

Centrifugal pumps often benefit from the addition of a shaft-mounted intake screw, or the selection of open-vane impellers. Elastomer rubber linings are sometimes recommended for fine sharps like sand, with high-chrome alloys frequently used for larger solids and high-flow or high-pressure pumps.

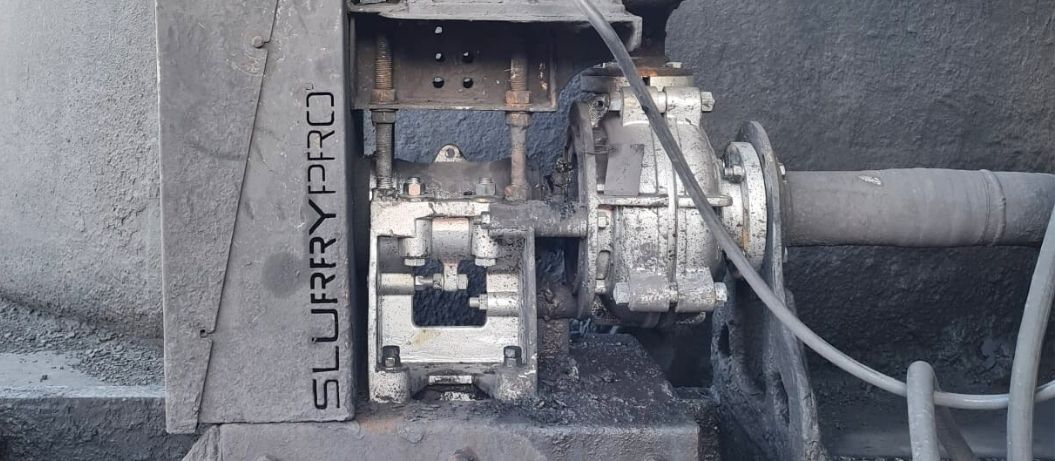

Standard progressive cavity pumps can be used for non-abrasive energy-crop feed stocks, but for municipal and other high-wear applications, a heavy-duty model designed for large solids passage will likely last longer.

Any high-speed rotation is asking for ragging problems, where even short fibres weave together to form blockages and restrictions. The answer to this is lower speed rotation, although the pipe diameter/chamber size might need to be increased to fulfil its volume requirements.

Industrial peristaltic pumps, such as the LSM, demonstrate good anti-ragging properties and can handle high DM (dry matter) and high solids content. The large diameter casing, coupled with the smooth action of their wide rollers, eliminates ragging occurrences as the shaft is isolated from the pumped media.

Although crop residues are generally less abrasive than general waste, the high lignin content can act as a micro-abrasive. This can be hard to spot, giving more of a subtle polish effect than deeper scratches. Nevertheless, the pump’s performance is negatively impacted over time, particularly with lobe pumps and progressive cavity pumps, as these rely on precise meshing of the internal surfaces.

Corrosion

Corrosive liquids in both EfW processes and Farm AD systems can include volatile fatty acids (VFAs) such as acetic and butyric acid.

Conclusion

Energy from Waste (EfW) developments, including the recovery of bioresources from wastewater treatment, is key to protecting the natural environment, mitigating climate change, and providing resilience in the UK’s energy security through diversity.

Despite the demand for increased environmental and climate protection, the industry faces headwinds from rising operational costs and fluctuating revenue returns from recycled and recoverable material.

This makes it more important than ever for EfW operators to maximise asset ROI, by cutting OPEX costs. The key areas of concern are energy performance, which reduces as wear rate increases, unplanned downtime, and the cost of maintenance. Capital budgets must be utilised with a TOTEX approach – measuring the lifetime cost of ownership rather than merely the initial project cost.

Need Support with Pump Selection for Your EfW Site?

Our experts can help you reduce wear, avoid downtime, and optimise performance for high-solids, abrasive, and corrosive applications.

We also take a sustainable approach to our work and are committed to reducing energy waste from pumps. Our expert knowledge allows us to reduce energy usage by 20% on the average site!

Call us today on 0808 196 5108 for more information.

July 23 2025

July 23 2025 6 min read

6 min read