Why is choosing the right sludge or slurry pump important?

Industries such as quarrying, heavy industry, and wastewater treatment require highly technical and specialised pumps that can withstand the complexity of solids-laden fluids being treated. The variety of suspended or entrained organic and mineral particles can make choosing a long-lasting, easily maintained pump a challenge. Slurry and sludge have different components and require different types of pumps depending on their specific characteristics. It is essential to understand the difference between the two, as well as the solids contained within the media, to choose the right pump for your specific application and operational requirements. Under-rated pumps and those design for clear liquids will prove costly to maintain, or even fail prematurely.

In this article, we will explain the differences between various types of organic and inorganic matter, as well as the characteristics to consider when selecting the ideal pump for your specific sludge needs.

Slurry And Sludge: The Definitions

Sludge is often described as a thick, viscous, semi-solid substance rich in organic content. Typically, in wastewater treatment applications, the organic, fibrous substances can easily block sludge pumps that aren’t properly suited for this application, resulting in costly downtime and even flooding or pollution issues. Even short fibres tend to ball together, as they wrap around spinning impellers, which puts a strain on the drive gear.

Slurry, on the other hand, is defined as a mixture of liquid and a high proportion of solids ranging from sand to large stones, and high lignin material which is usually found in environments like mining, farming and quarrying. Specific types of slurry pumps should be used for sand and silt components, as they tend to have a highly abrasive content.

There isn’t a universal agreement on the defining point between sludge and slurry, and it usually relates to its flowability (or lack of) rather than total solids (TS) content. Many factors can influence the flowability/viscosity of a fluid: temperature, particle sizes, shear rate, and solids percentage. The solids percentage to viscosity of sewage sludge is non-linear; in one study, just doubling the solids in sewage sludge, from 6% to 12%, resulted in a viscosity increase factor of 25 (Cheng & Li, 2015).

Yet, being able to pump higher viscosity matter can deliver big prizes. When you consider what doubling the TS means; reduction of water content by 50% – the savings in storage and transport costs can make this well worthwhile. The Audex pump is one of the few types that can handle this higher level of sludge viscosity without the excessively rapid wear and energy performance issues that affect other families of sludge pumps.

Characteristics Of The Ideal Pump

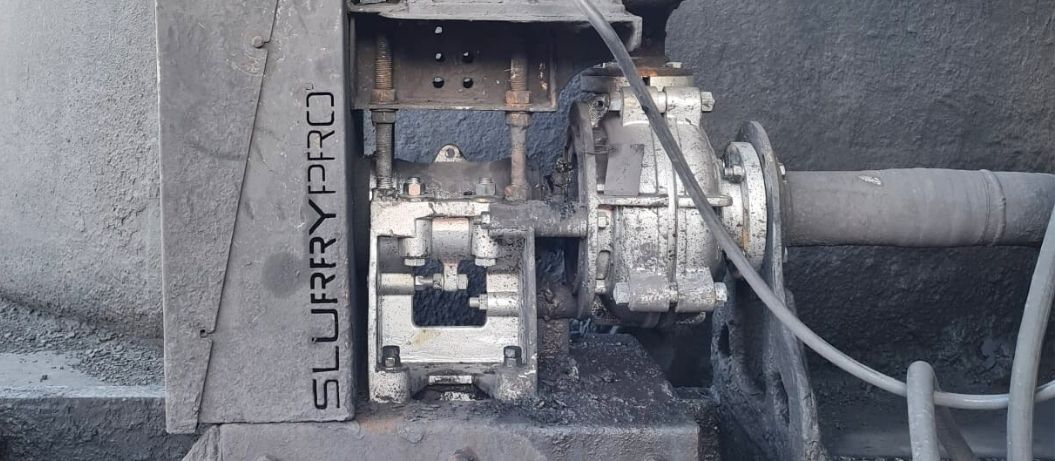

Sludge’s biggest pumping challenges tend to arise due to its density levels, which cause pumps to clog, consume more energy, or break down. The ideal equipment would have the ability to handle high-viscosity levels and have high levels of abrasion resistance without demanding excessive maintenance. Sludge pumps used in wastewater treatment plants should have high clogging resistance, and in certain applications, also be able to tolerate dry running periodically, ensuring they can successfully treat sludge. Specialist pumps, such as SlurryPro centrifugal pumps or LSM peristaltic pumps (depending on viscosity levels), provide a steady flow despite the complexity of the media handled. These pumps are often more expensive to purchase than standard water pumps; however, operators who have adopted them now see them as essential for avoiding downtime and high operational costs.

When pumping slurry, expect your challenges to be drastically different from those encountered in clean water duties, due to the difference in particle size and the mix of soft and hard solids. For example, in quarrying applications, slurry pumps should be able to handle high abrasion levels while moving aggregates and other mixtures rich in minerals, some of which can be at a low or high pH naturally. Centrifugal pumps suitable for slurries are usually best suited in high-flow, low-pressure environments, and are built to withstand large amounts of abrasive fluids. This is why it is essential to understand the options available in pump materials and design, as the cheaper pumps can prove to be the most costly option when premature wear and tear occurs, or if the pump supplied requires more electricity to deliver consistent results.

Which Pump Should I Choose?

The choice between different types of pumps should ultimately be determined by your needs and the nature of the solids content in the sludge or slurry being treated and transported. Once you have chosen the pump type and manufacturer that best covers your industry and duty, you can then refine your search to the right size for the required flow and head height pressure.

Choosing the lower-priced or smaller pump will often lead to unsatisfactory results, however, considering that energy costs far outpace the initial purchase price of a pump, going over-size won’t necessarily lead to success in the long run. In fact, businesses that fail to invest in the correct pump for their specific needs are known to face significant downtime, unreliability, and increased maintenance costs.

It is important to understand and assess the components of the sludge or slurry matter you are dealing with, particularly abrasion and viscosity levels, solids size, flow and pressure behaviour. Choosing the right pump can help increase your productivity levels and avoid unnecessary dives into your operating budget. If you are handling thick sludge, consider using LSM or Toro-Kronoa PC pumps, as they are designed to resist blockage and handle high ‘dry matter’ sludges. On the other hand, consider using pumps such as SlurryPro or Audex submersibles to ensure durability and wear resistance whilst transporting aggregate-heavy slurries in your quarry.

How Atlantic Pumps Can Help

If you are unsure which pump is best suited for your needs and application, or if you have any questions, please contact us, as we will be happy to answer any questions you might have.

Need the Right Pump for Your Sludge or Slurry?

Download our free guide 'Managing Grit and Sludge' to learn proven solutions.

We also take a sustainable approach to our work and are committed to reducing energy waste from pumps. Our expert knowledge allows us to reduce energy usage by 20% on the average site!

Call us today on 0808 196 5108 for more information.

August 13 2025

August 13 2025 4 min read

4 min read