Industrial pumps face a relentless enemy: wear and tear. Although modern pumping assets are tough machines designed to handle a variety of difficult environments, gradual exposure to abrasive solids such as sand and gravel will eventually wear down even the toughest equipment.

So…

‘How do I protect my pumps and maximise their lifespan?’

If you’ve asked this question, the answer lies in taking a smart and proactive approach to system design, procurement, and maintenance. Here are five proven strategies to protect your pumps from wear and tear.

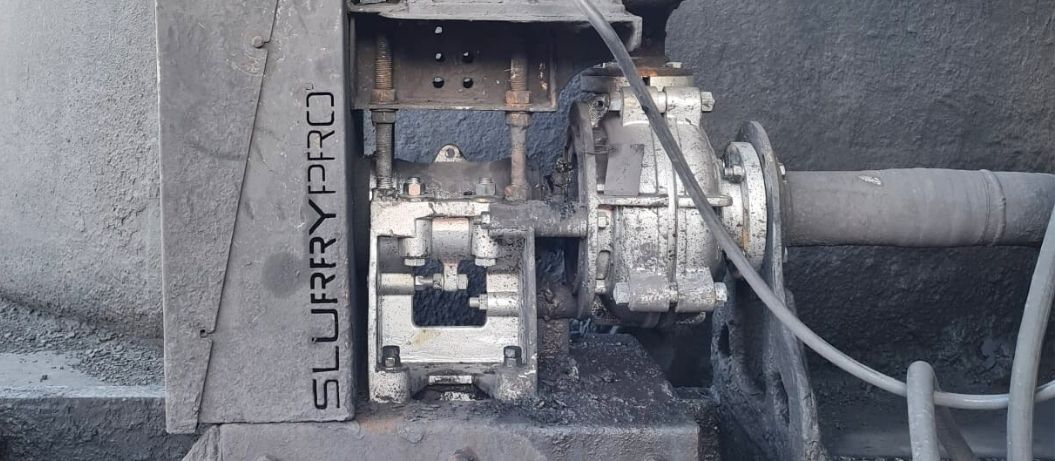

1. Invest in a heavy-duty pump design

The first line of defence against abrasive wear is choice of pump. Most standard pumps are designed for non-abrasive fluids such as clear water, and cannot handle the harsh conditions faced in quarries, mines, and construction sites. Typically, you’ll see a steep drop in performance, increased energy draw, and wear rates that will result in failure sooner or later. To counter this, invest in a pump specifically designed for abrasive applications. These specialist pumps often come with heavy-duty casings and replaceable liners that provide a strong physical barrier against damage. The design allows the liner to absorb the brunt of the abrasive impact, sacrificing itself to protect the more expensive pump casing, and when the liner wears out, you can simply replace it (instead of the entire pump), saving considerable time and money. You can also increase the solids performance of your system by installing impellers with large clearances designed to allow fibre and debris to pass through without blocking or damaging the pump. This increases both the reliability and the performance characteristics of the pump, even when faced with high concentrations of abrasive solids.

2. Choose high-quality, wear-resistant materials

As we’ve seen, design plays a strong role in the way that a pump withstands wear and tear in abrasive or corrosive environments, but the material composition of your pump also has a direct impact on its durability and lifespan. Many standard pumps are made from grey cast-iron, and while these might suffice for clean water applications, they can quickly degrade when exposed to harsh slurries. For dealing with abrasive solids, high alloy white cast-iron is the material of choice, withstanding both the grinding action of particles and the corrosive fluids frequently found in wastewater treatment.

3. Monitor your pumping systems

Ultimately, you can’t resolve a problem that you don’t know exists, which is why many organisations still fall back on an ‘if it ain’t broke, don’t fix it’ approach to maintenance. However, this run-till-failure attitude can cause all sorts of problems and unnecessary expense.

Modern monitoring technology offers a more nuanced and effective approach to maintenance, giving you crucial insight into your pump’s health and early warning of a wide range of impending problems. By continuously tracking key performance indicators through a network of sensors, you can keep your pump operating at its Best Efficiency Point (BEP). Running a pump too far from its BEP can lead to recirculation, excess vibrations, wasted energy, and accelerated wear, so it’s important to keep a close eye on any anomalies and unexpected patterns. A data-driven approach to pump protection also helps you move away from reactive repairs to predictive maintenance, scheduling services before a catastrophic failure occurs.

4. Keep your seals lubricated and aligned

A pump’s mechanical seal is its most critical and vulnerable component. The seal prevents fluid from leaking out and keeps contaminants from entering the pump, so if this fails, the bearing might be the next to go, leading to fluid loss and motor damage. Keeping the seal constantly lubricated is essential to prevent this scenario. In many wastewater applications, a continuous flush of clean liquid is used to cool the seal face and prevent abrasive particles from getting in. Alignment between the pump and motor is also essential, as misalignment can put excess strain on the seals and bearings, increasing the rate of wear and tear and raising the risk of premature failure. Regular lubrication and alignment checks should become a standard part of your maintenance routine, if they are not already.

5. Invest in operator training and awareness

Technology can only go so far, with a well-designed pump protection system being only as effective as the person operating it. Regular and comprehensive training is, therefore, essential for keeping your team up to speed on the pump’s capabilities and limitations, and to help them recognise the early warning signs of an underlying issue. A trained operator is better equipped to recognise unusual operating patterns and take corrective action before damage is done. Empowered with greater knowledge, your operators will become an active part of your maintenance and reliability strategy, reducing the risk of premature wear.

Book an online training session to upskill your team.

Technology can only go so far, with a well-designed pump protection system being only as effective as the person operating it. Regular and comprehensive training is, therefore, essential for keeping your team up to speed on the pump’s capabilities and limitations, and to help them recognise the early warning signs of an underlying issue. A trained operator is better equipped to recognise unusual operating patterns and take corrective action before damage is done. Empowered with greater knowledge, your operators will become an active part of your maintenance and reliability strategy, reducing the risk of premature wear.

We also take a sustainable approach to our work and are committed to reducing energy waste from pumps. Our expert knowledge allows us to reduce energy usage by 20% on the average site!

Call us today on 0808 196 5108 for more information.

January 2 2026

January 2 2026 3 min read

3 min read