Choosing robust, efficient pumps with a low total ownership cost is crucial for any wastewater treatment business. You need to handle everything from trade effluent to sewage sludge, and the right pump in the right place is crucial for successful, streamlined operations. The specific wastewater treatment pump you choose will depend on the type of wastewater being processed and its stage in the multi-step treatment process. Flow rate, duty cycles, pressure head, abrasiveness, solids content, energy effectiveness and total lifetime costs (TOTEX) all need consideration.

Pumps made for clean water will likely sustain damage or premature wear if used for wastewater, causing sudden failure or a steep drop in performance and efficiency.

Having the right pumps in place can make your wastewater treatment process more efficient and ultimately reduce ongoing operational costs (Opex). Pumps at the headworks must effectively pass large solids, while flow-rate to energy consumption is key throughout the treatment process. High viscosity, abrasion-resistant, and rag-tolerant pumps are crucial for moving dewatered sludge, silt and fibrous media.

Pump Challenges

Wastewater treatment plant companies may face several issues when pumping water through their systems because wastewater will often contain debris, which impacts efficiency. It’s essential that the right pump is chosen, to minimise challenges such as:

- Blocked pumps – This is a common issue because wastewater often contains debris, which can impact the flow rate and increase resistance, leading to sudden blockage or gradual buildup. Prolonged pump downtime risks flooding and other environmental incidents.

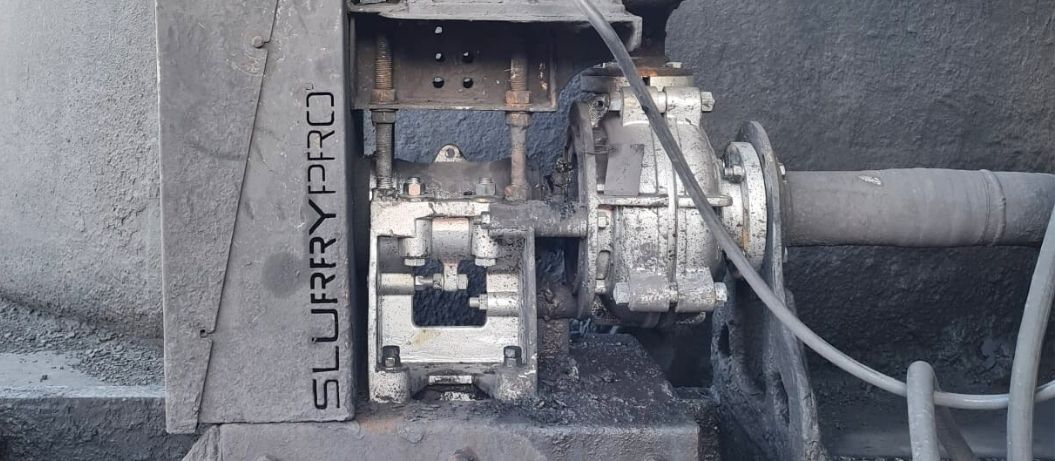

- Equipment abrasion – Wastewater with entrained solid particulate matter means the types of pumps used in wastewater treatment plants need to withstand a high degree of wear and tear. Even fine particulates can have a severe abrasive action on pump parts, pushing up the cost of maintenance and replacement.

- Chemical and pH damage – Some chemicals used in wastewater treatment plants are highly corrosive, leading to a higher rate of pump degradation and corrosion. The pH of wastewater can range from acidic to highly alkaline, requiring careful material selection for the ‘wet-parts’.

The Different Pump Options

There are four common pump types suitable for the wastewater industry. All come with their own advantages and disadvantages depending on the wastewater’s charactistics, and the duty:

1. Centrifugal Pumps

Centrifugal pumps operate by using centrifugal force – an impeller rotates inside the pump, pushing fluid outwards from the centre and into the pump’s discharge.

Centrifugals designed for the wastewater treatment process are fitted with open impellers because they don’t tend to clog so easily as their clean water counterparts. Split-casing makes maintenance and inspection easier, and high-wearing materials can be specified for abrasive fluids. Designed to pump fluids continuously, any parts that are wearing out can simply be replaced rather than having to replace the entire pump unit.

Their main positive attributes are high-flow rates, and pressure building potential. As CF pumps add kinetic energy to the supply pressure, they can be connected in series to reach high head pressures. Pumps made like this are called multi-stage pumps.

2. Submersible Pumps

Submersible pumps are another type of pump commonly used in the water industry. These watertight pumps operate within the wastewater they are pumping, making them highly effective for frequent on/off cycling. Good industrial models are fitted with seal failure devices, which protect against motor failure.

Parts such as impellers and wear plates are made from iron or high-chrome alloy to reduce wear and tear and increase lifespan. Some will come with an agitator to keep silt in suspension and reduce the risk of clogging.

3. Progressive Cavity Pumps

Progressive cavity pumps have a unique screw design, invented by René Moineau. The design has multiple rotating chambers that progressively push fluid along the length of the pump. The advantage of this is it ensures predicatble fuid pressure and consistent flow rates.

They’re ideal for usage in the water industry where a seamless, efficient and continuous process is required. They’re capable of handling viscous sludges and, with the right stator/rotor geometry, fluids with suspended solids. Because they’re particularly suited to handling wastewater sludges, they can aid in increased efficiency and cost effectiveness of wastewater treatment. In addition, they also require less energy to run than some other types of pump.

4. Industrial Peristaltic Pumps

Large, industrial peristaltic pumps (hose pumps) have been developed to transfer highly viscous sludge and near-dry sludge. With these pumps, a section of flexible pipe fits around a rotating arrangement of rollers which squeeze the media to generate flow.

The hoses can be made from abrasion-resistant rubber, which is both long-lasting and inexpensive to replace. As a positive displacement pump, peristaltics are able to produce good flow and pressure with lower rotation speed than a centrifugal pump.

The Right Pump, in the Right Place

Different industrial pumps will suit different applications – we can tailor solutions to your type of effluent and treatment-specific requirements. Bring your wastewater challenges to us and we will help you find the right high-quality pumps to do exactly what you need. Ram pumps, diaphragm pumps, centrifugals, we’ve got you covered. Call 0808 196 4938 or complete our contact form.

We also take a sustainable approach to our work and are committed to reducing energy waste from pumps. Our expert knowledge allows us to reduce energy usage by 20% on the average site!

Call us today on 0808 196 5108 for more information.

July 5 2024

July 5 2024 3 min read

3 min read