Pumps 2000

AODD pumps to outlast all others – meet the Megator Pumps 2000 range

The Pumps 2000 range covers specialist media and ATEX zoned pumping duties. Atlantic Pumps are official UK distributors of Pumps 2000 AODD pumps.

Megator – Pumps 2000 offers a wide range of patented, non-metallic Pneumatic Diaphragm pumps that out-perform and outlast all others.

Pumps 2000 is a family of pumps made of advanced non-metallic materials, making them ideal for caustic chemical, acid, or flammable liquids pumping in ATEX zoned areas.

Lightweight and ATEX certified, there are anti-static and fire resistant models available, and those compatible with many different chemicals and pH ranges.

Air-operated double diaphragm (AODD) pumps are powered by compressed air that can be generated at a safe distance away from the pump itself. This makes the pump itself lighter, quieter, and safer, and simipler to maintain than engine or electric motor driven diaphragm pumps.

Pumps 2000 have made full use of this by developing ATEX certified and Anti-Static versions, using non-metallic polymer material. Established in Australia in 1989 they have grown their range to cover many specialised pumping duties in mining, chemicals, and general industry. This is one of very few diaphragm pump brands that offer a slurry valve option, bringing the benefits of AOD positive displacement pumping to dirty water sludges with suspended solids.

If you require a lower risk positive displacement pump for slurry, hazardous media and environments, the Pumps 2000 AOD range is highly likely to yield the configuration you need.

Pumps 2000 – Yellow Pumps

The Yellow Series have their pump housing constructed with a specialist nylon blend material which is food-grade and withstands saline/salt water, and some acids.

- General water and slurry duties in ATEX M2 applications.

- Salt brine and high salinity suitable pumps, ideal for marine duties, rare earth brine concentration and ion exchange applications.

- 4” (100mm) High Volume can reach 122 m3/hr flowrate and pass 3” solids.

- Portable (5 – 30kg) models with maximum flow rate of 62 – 814 L/min.

- Double stage, double diaphragm model available for up to 140m head pressure

The Pumps 2000 range

AODD Red Series (FRAS)

Built for continuous pumping in hazardous explosive atmoshperes, this range is designed for fire resistance and explosion-proof operation in the highest risk zones – underground mines, and situations where methane, explosive dust or flammable gas presents a risk.

- ATEX M1 Rated

- Fire Resistant and Anti-Static

- Lightweight

- Pump housing made from of special nylon-based blend, with Hytrel elastomer internals as standard.

- Low viscosity (water) version and slurry/suspended solids versions.

- Single stage versions in 1/2” to 3” inlet (15mm – 75”), and a double stage, higher pressure model in 2” (50mm) for up to 140m head pressure

AODD Blue Series

- ATEX M2 Rated

- Compatible with a wide range of acids, and caustic chemicals

- Max flowrates of 530L/min – 800L/min (32 – 48m3/hr) depending on slurry type

- Up to 70m max dynamic head

- Largest slurry model passes solid sizes of up to 46mm

- Santoprene internal parts – for chemical resistance

- Pumps weigh only 3.6kg – 24kg (about a third of equivalent cast iron pumps)

Pumps 2000 answer to settling solids and sludge

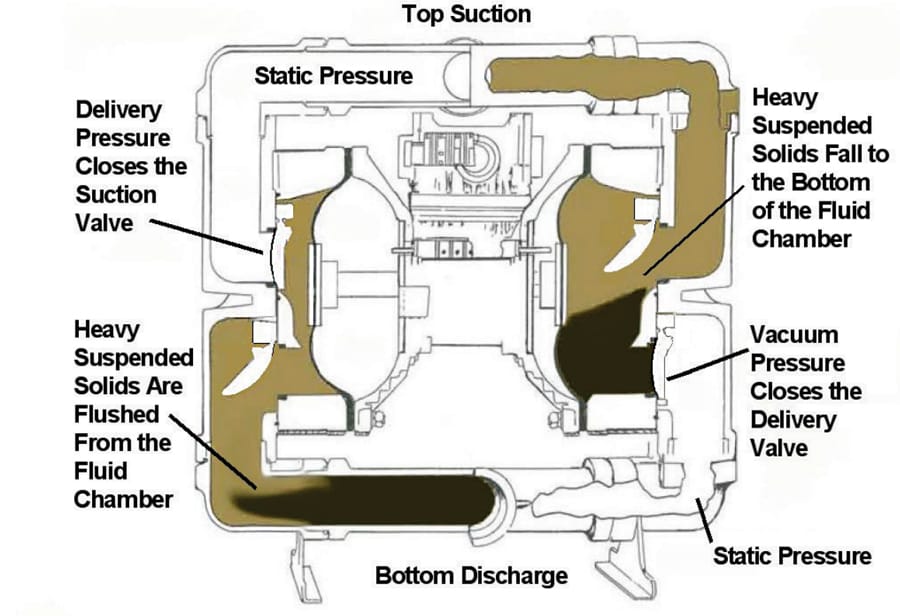

Clean water and clear fluid AOD pumps are generally fitted with ball valves to close the intake during compression cycles. However, this casues issues if any solids, such as sand grains settle in the valve and prevent it sealing properly.

For this reason, Pumps 2000 developed a special arrangement for slurry pumping, which prevents the valve sticking open and results in settling sludge being flushed through with each cycle.